Ball valves

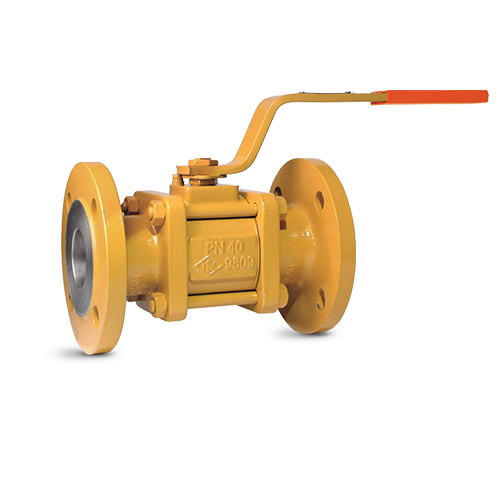

1400 / BALL VALVE

| PRODUCTION STANDARDS | |

| DN15 → DN150 PN 16-25-40 |

|

| Design | EN 331 – TS 9809 |

| Connection | EN 1092-2 / ISO 7005-2 |

| Face to Face | DN15-DN125: EN 558 Series 1 / DIN3202 F1 DN150: EN 558 Series 28 / DIN3202 F7 |

| Marking | EN 19 |

| Tests | EN 12266-1 |

| Corrosion Protection |

Industrial Epoxy |

- Features

FAF1400, PN 40 flanged ball valve is operating by a ball having a hole with the same size as the flow section, through the help of the stem, rotating quarter turn (90 degree) between teflon seats where the ball to be parallel or perpendicular to the flow axis. - Can be installed bidirectional.

- Through the stainless steel belleville spring reinforced teflon (PTFE) seats, 100% tight sealing is achieved in lowest and highest pressure ratings.

- Can be installed directly to the pump without any need for additional intermediary parts.

- The compatibilty of teflon material with various flow types and its resistance to higher temperatures enables it to be used in wide range of applications.

- It is appropriate to be used in fully open or fully closed position.

- In fully open position, since there is no reduction in flow section, the head loss is nearly zero.

- Can be operated with lower torque ratings.

Temperature

+200 °C

Scope of Application

- LPG

- Natural gas

- Superheated water

- Low

- Power plants

- Industry

- Fluids without acidity or alkalinity properties

- Chamber installation

- Installation in plants

- Pipelines

- Tanks

- Industry